Trophy spraygun Troubleshooting

- Symptom1 - Heavy top or bottom pattern

- Symptom2 - Heavy right or left side pattern

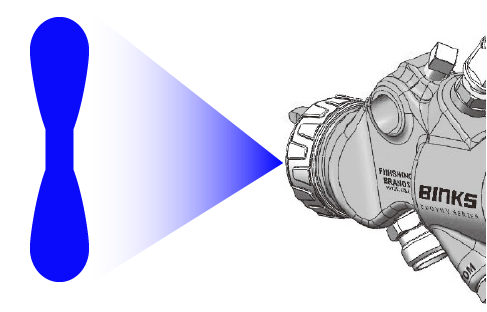

- Symptom3 - Heavy center pattern

- Symptom4 - Split spray pattern

- Symptom5 - Jerky or fluttering spray

- Symptom6 - Unable to get round spray

- Symptom7 - Will not spray

- Symptom8 - Paint bubbles in cup

- Symptom9 - Fluid leaking or dripping from cup lid

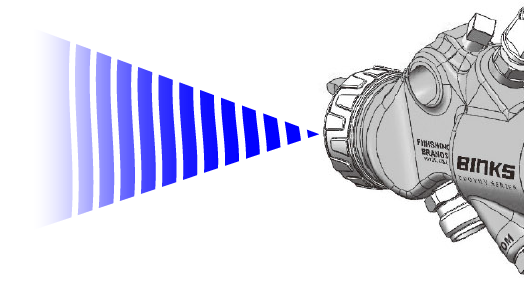

- Symptom10 - Starved spray pattern

- Symptom11 - Excessive overspray

- Symptom12 - Excessive fog

- Symptom13 - Dry spray

- Symptom14 - Fluid leaking from packing nut

- Symptom15 - Fluid leaking or dripping from front of gun

- Symptom16 - Runs and sags

- Symptom17 - Thin, sandy coarse finish drying before it flows out

- Symptom18 - Thick, dimpled finish "orange peel"

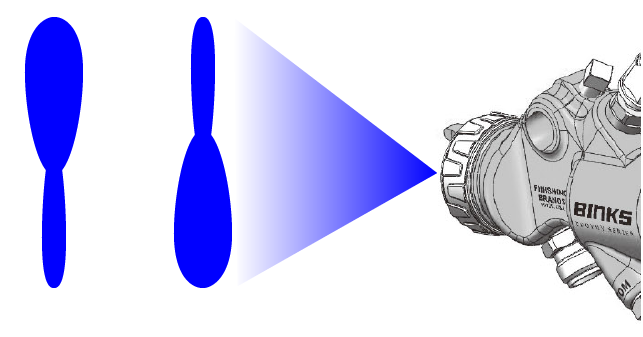

Symptom1 - Heavy top or bottom pattern

Possible Cause

- Horn holes plugged.

- Obstruction on top or bottom of fluid tip.

- Cap and/or tip seat dirty.

Remedy

- Clean. Ream with non-metallic point.

- Clean.

- Clean.

Symptom2 - Heavy right or left side pattern

Possible Cause

- Left or right side horn holes plugged.

- Dirt on left or right side of fluid tip.

Remedy

- Clean. Ream with non-metallic point.

- Clean.

■Remedies for the top-heavy, bottom-heavy, right-heavy, and left-heavy patterns:

- Determine if the obstruction is on the air cap or the fluid tip. Do this by making a test spray pattern. Then, rotate the cap one-half turn and spray another pattern. If the defect is inverted, obstruction is on the air cap. Clean the air cap as previously instructed.

- If the defect is not inverted, it is on the fluid tip. Check for a fine burr on the edge of the fluid tip. Remove with #600 wet or dry sand paper.

- Check for dried paint just inside the opening; remove by washing with solvent.

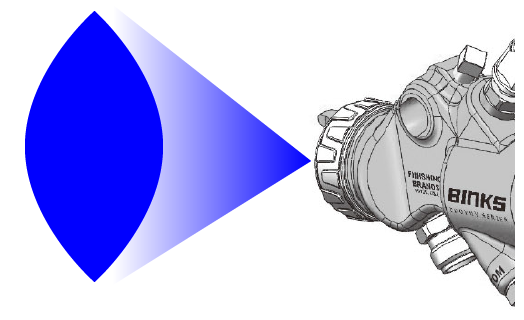

Symptom3 - Heavy center pattern

Possible Cause

- Fluid flow too high for atomization air.

- Material flow exceeds air cap’s capacity.

- Spreader adjustment valve set too low.

- Atomizing pressure too low.

- Material too thick.

Remedy

- Balance air pressure and fluid flow. Increase spray pattern width with spreader adjustment valve.

- Thin or lower fluid flow.

- Adjust.

- Increase pressure.

- Thin to proper consistency.

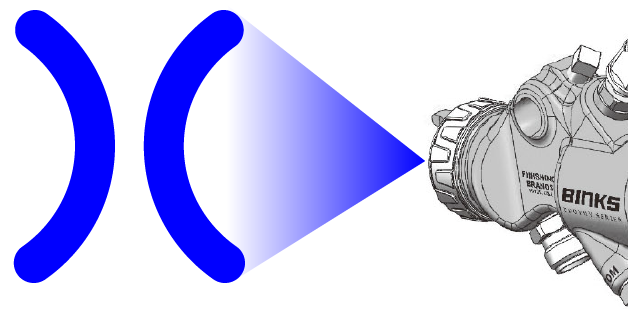

Symptom4 - Split spray pattern

Possible Cause

- Atomization air pressure too high.

- Fluid flow too low.

- Spreader adjusting valve set too high.

Remedy

- Reduce at transformer or gun.

- Increase fluid flow (increases gun handling speed).

- Adjust.

Symptom5 - Jerky or fluttering spray

Possible Cause

- Loose or damaged fluid tip/seat. (Most common problem)

- Material level too low.

- Container tipped too far.

- Obstruction in fluid passage.

- Dry or loose fluid needle packing nut.

Remedy

- Tighten or replace.

- Refill.

- Hold more upright.

- Backflush with solvent.

- Lubricate or tighten.

Symptom6 - Unable to get round spray

Possible Cause

- Spreader adjustment screw not seating properly.

- Air cap retaining ring loose.

Remedy

- Clean or replace.

- Tighten.

Symptom7 - Will not spray

Possible Cause

- No air pressure at gun.

- Fluid needle adjusting screw not open enough.

Remedy

- Check air supply and air lines, blow out gun air passages.

- Open fluid needle adjusting screw.

Symptom8 - Paint bubbles in cup

Possible Cause

Fluid tip not tight.

Remedy

Tighten tip.

Symptom9 - Fluid leaking or dripping from cup lid

Possible Cause

- Cup lid loose.

- Dirty threads on cup or lid.

- Cracked cup or lid.

Remedy

- Tighten lid.

- Clean.

- Replace cup and lid.

Symptom10 - Starved spray pattern

Possible Cause

- Inadequate material flow.

- Low atomization air pressure.

Remedy

- Back fluid adjusting screw out to first thread, or change to larger tip size.

- Increase air pressure and rebalance gun.

Symptom11 - Excessive overspray

Possible Cause

- Too much atomization air pressure.

- Gun too far from work surface.

- Improper stroking (arcing, gun motion too fast).

Remedy

- Reduce pressure.

- Adjust to proper distance.

- Move at moderate pace, parallel to work surface.

Symptom12 - Excessive fog

Possible Cause

- Too much or too fast-drying thinner.

- Too much atomization (air pressure.)

Remedy

- Remix properly.

- Reduce air pressure.

Symptom13 - Dry spray

Possible Cause

- Air pressure too high.

- Gun tip too far from work surface.

- Gun motion too fast.

- Gun out of adjustment.

Remedy

- Reduce air pressure.

- Adjust to proper distance.

- Slow down.

- Adjust.

Symptom14 - Fluid leaking from packing nut

Possible Cause

- Packing nut loose.

- Packing worn or dry.

Remedy

- Tighten, do not bind needle.

- Replace or lubricate.

- Packing nut too tight.

- Dry packing.

- Fluid tip or needle worn or damaged.

- Foreign matter in tip.

- Fluid needle spring broken.

- Wrong size needle or tip.

- Adjust.

- Lubricate.

- Replace tip and needle.

- Clean.

- Replace.

- Replace.

- Too much material flow.

- Material too thin.

- Gun tilted on an angle, or gun motion too slow.

- Adjust gun or reduce fluid flow.

- Mix properly or apply light coats.

- Hold gun at right angle to work and adapt to proper gun technique.

- Gun too far from surface.

- Too much air pressure.

- Improper thinner being used.

- Check distance. Normally approximately 8".

- Reduce air pressure and check spray pattern.

- Follow paint manufacturer’s mixing instructions.

- Gun too close to surface.

- Too much material coarsely atomized.

- Air pressure too low.

- Improper thinner being used.

- Material not properly mixed.

- Surface rough, oily, dirty.

- Check distance. Normally approximately 8".

- Follow paint manufacturer’s mixing instructions.

- Increase air pressure or reduce fluid flow.

- Follow paint manufacturer’s mixing instructions.

- Follow paint manufacturer’s mixing instructions.

- Properly clean and prepare.

Symptom15 - Fluid leaking or dripping from front of gun.

Possible Cause

Remedy