Paint Circulating Equipment

Paint Circulating Equipment

BINKS Mission

Our Mission is to work in partnership with our customers’ process requirements and collaborate together to ensure we achieve cost effective valued solutions.

This vision is motivated by 2 Key business philosophies in compliance with the Automotive market demands for quality and integrity:

- Continual Innovation to achieve reliable and efficient products and processes

- Market feedback via direct end user technical support and hands-on approach

History

In 1890, Joseph Binks pioneered the spray gun industry with the introduction of the first cold-water paint spraying machine. Binks used his invention to rescue the opening of the 1896 Colombian Exposition. Just days before the opening, nine of ten exhibit buildings stood unpainted, but Binks saved the day. Today you will find spray finishing and paint circulating technology from Binks at work in virtually every industry around the world.

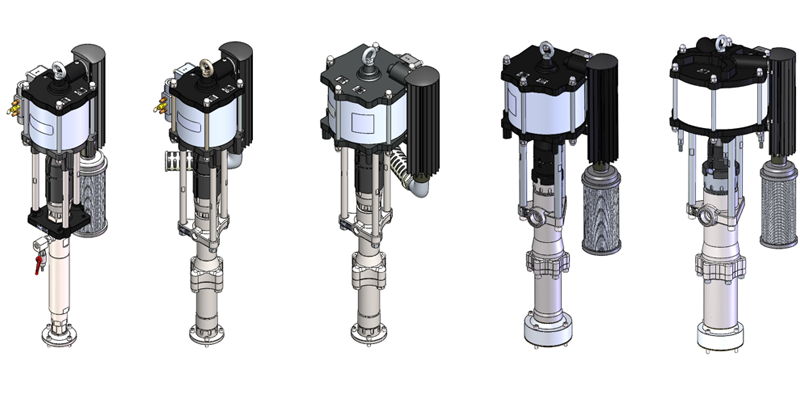

SMART Pumps - Think Smart, as for your performance as for the environment

The unit combines conventional electrical hardware to achieve optimum operating performance at a lower cost. Running costs are much lower than compressed air driven model.

Used with an optional smart card, high savings in running cost can be realized, by delivering the paint to the user point at the correct pressure and volume only when needed.

The SMART pump range uses a standard electric motor to drive the fluid section for pumping paints, solvent and other suitable materials, reducing paint shear due to the positive dissplacement piston design and thanks to a cam and cam followers combined with a sliding carriage unit without required surge chamber.

SMART Pumps

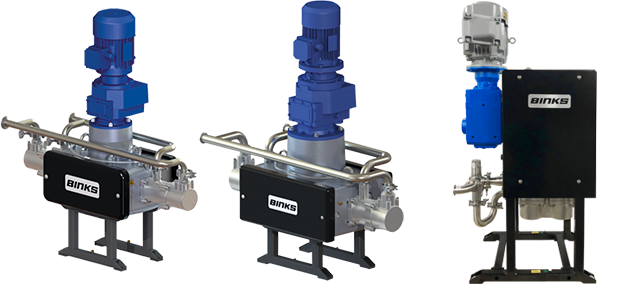

MAPLE Pumps - For an efficient and environmentally friendly Paint Circuit

The Maple Pump is a horizontal piston pump for pumping Solvent / Waterborne Paints, Solvents and other suitable materials. The unit combines an energy efficient air motor with low shear fluid section technology from the range of Smart Electric Pumps to ensure balanced fluid pressure output and a minimum of fluid pressure fluctuations.

The Maple Pump achieves a reciprocating drive by using high tolerance steel spool and sleeve air valve to control the air motor reversal, providing reciprocating motion. The patented air valve design ensures a positive magnetic detent for the main air valve thus removing the possibility for a stall condition.

The air motor also utilizes the patented Binks Low Ice quick exhaust technology

to prevent air valve freezing conditions when high cycle speeds are employed.

MAPLE Pumps

Products

-

MX Pumps

In order to deal with the increasingly difficult demands of high viscosity application in the Automotive & Industrial markets, BINKS offers a complete range of high pressure pumps.

Ball check pumps for medium to high viscosity materials or chop check pumps for very high viscosities can be supplied. -

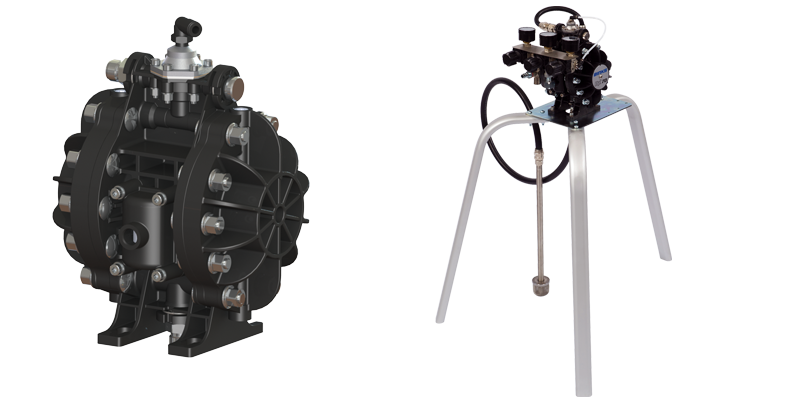

Infinity Diaphragm Pumps

Binks infinity diaphragm pumps have made large volume delivery possible and they are highly durable. Ideal for abrasive coatings, high solids and shear sensitive paints. Highly reliable as the paint supply for HVLP and LVMP, and also the perfect option for a tight budget.The pump will not be damaged even when you have run out of the paints. Infinity diaphragm pumps can be used widely from just one gun to large volume supply using multiple guns.

-

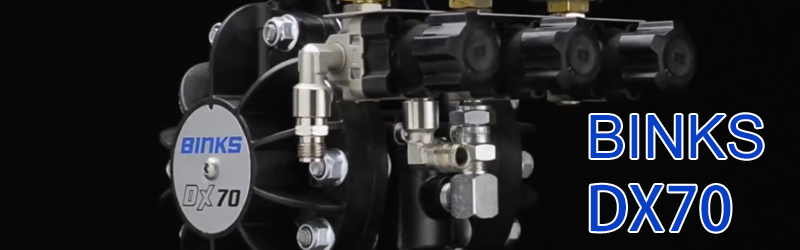

DX Pumps

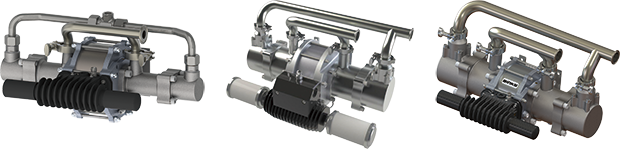

The DX Pump Series is a Family of positive displacement pumps that use a combination of the reciprocating action of a rubber and PTFE composite diaphragm and suitable check valves to pump literally any known fluid.

-

Surge Eliminator

Self compensating design eliminating manual charging with compressed air.

Active feature dynamically changes Air pressure automatically to equal fluid pressure.

Elimination of paint surge due to pressure fluctuation. -

Binks Ram Units

Binks Ram Units provide the ideal delivery solution for materials such as lubricants, mastics, adhesives, epoxies and sealants. They deliver a constant, low pulse flow of material to the dispensing tool by ensuring correct priming of the pump and preventing material cavitation.