Electrostatic coating

Electrostatic coating

CFT Ransburg offers you an ideal coating system

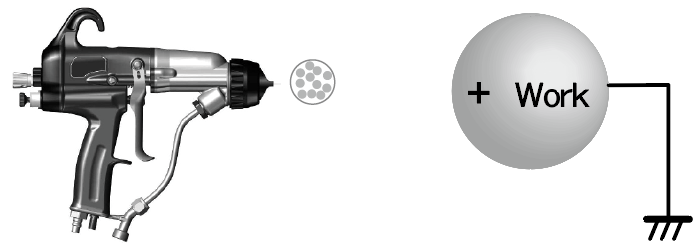

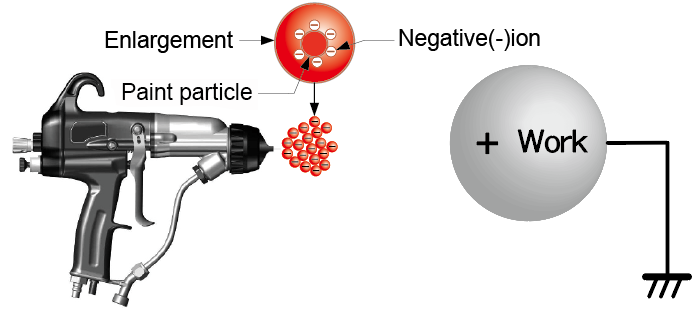

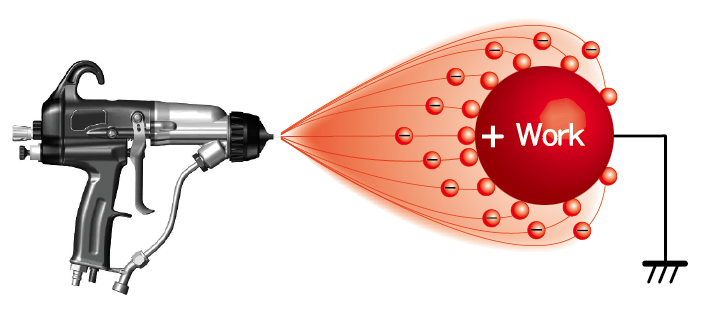

The work piece to be coated is attached to a positive electrode (grounded) and an applicator is attached to the negative electrode. In this coating technology a high voltage supply is utilized to create an electrostatic field between the two electrodes. Atomized particles of paint, receiving a negative charge, are attracted rapidly and evenly to all areas of the positively charged work piece, even to the sides and the rear. The advantages of this electrostatic coating technology are that it not only saves a large amount of coating material, but also results in a reduction in the coating time through the improvement of coating capacity. Material savings, protecting the working environment and also bringing us high added value as a technology for safeguarding the natural environmental - these are the reasons why the electrostatic coating process, an innovative technology, is widely chosen.

Products

-

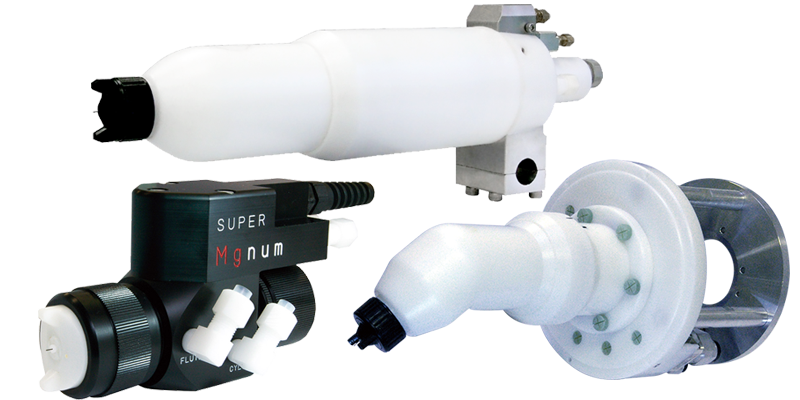

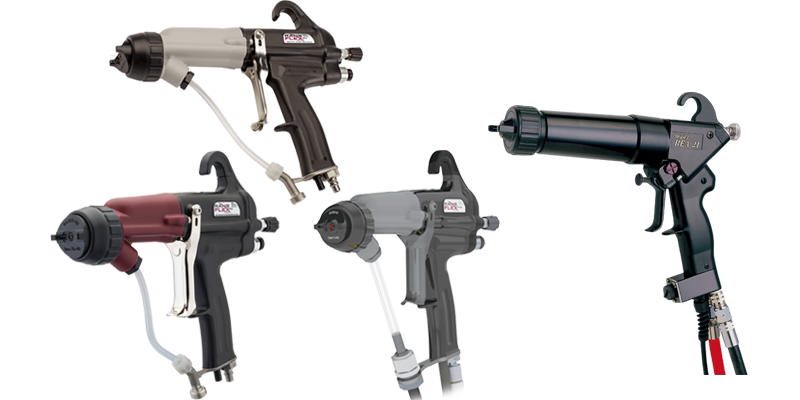

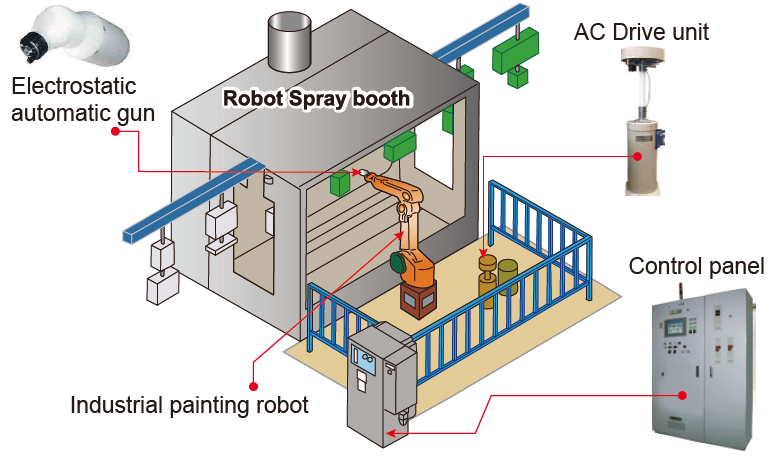

Electrostatic auto spray guns

"RAgent Series," "Mighty Series," "Robot REA gun," "SuperMgnum" etc.

-

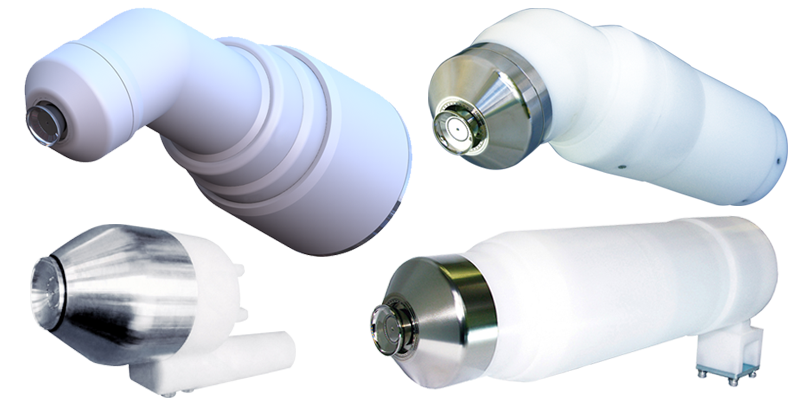

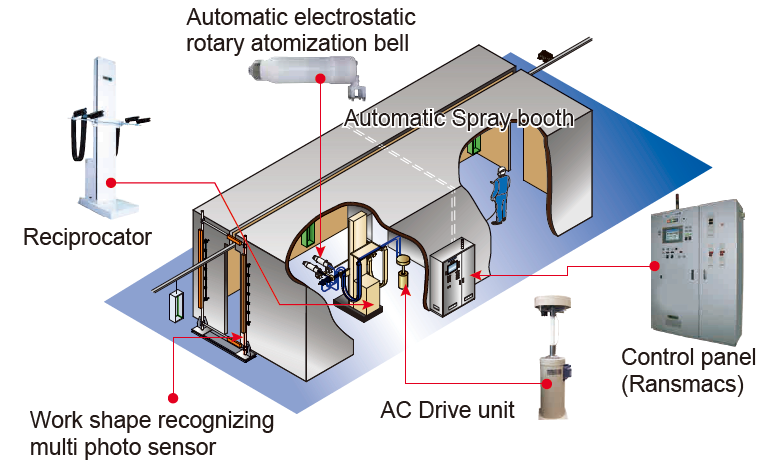

Automatic Electrostatic Rotary Atomization Bell

Electrostatic Rotary Atomization System.

For robot-mounting, General Industrial applications, Variable Pattern -

Disk

Electrostatic Rotary Atomization System. Dramatically improve paint atomization performance.

-

Electrostatic hand spray guns

Air Driven Type High Performance Finishing "RansFlex Series," 600g light weight Electrostatic hand spray gun "REA gun" etc.

Electrostatic coating

The electrical field between the ionizing needle and the grounded object helps drive the charged spray particles to the grounded target. The force of the electrostatic field cause a greater percentage of the charged spray particles to reach the grounded object, rather than miss the target or be swept away by surrounding air flow.

1.Ionization at the point-end of the gun

2.Paint particles are negatively charged

3.Negatively charged paint articles are attracted to the work piece

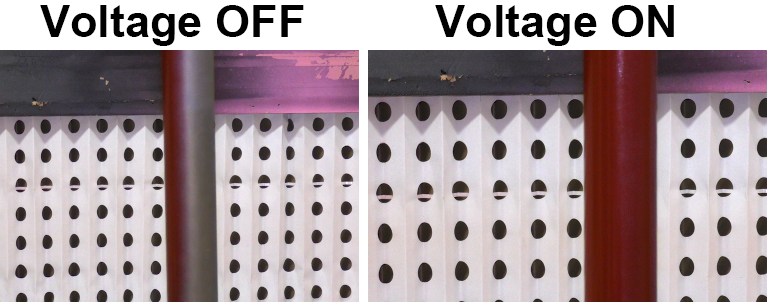

Comparison between Air spray gun and Electrostatic spray gun

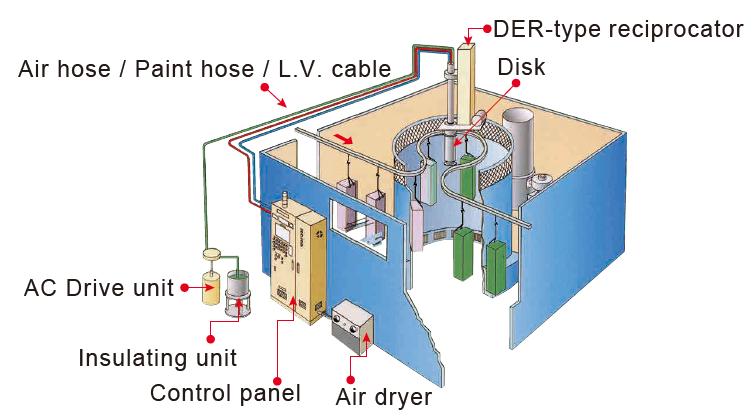

BELL SYSTEM

featuring (a) fine and uniform paint particles out from high speed rotary bell cup, (b) pattern adjustment by shaping air pressure and (c) high transfer efficiency suitable to :

- Fine finish coating

- Light weight objects

- High viscosity paint (coating without using thinner)

- Difficult atomization paint

GUN SYSTEM

featuring (a) variety of use, (b) easier condition set-up and (c) easy operation suitable to :

- Various kinds and low volume production

- Complicated shape object

- Random production

- Metallic coating

DISK SYSTEM

featuring (a) good for a number of coatings with thin layer, (b) no air required for paint atomization and therefore (c) quite suitable to the followings:

- Little kind and plentiful production

- Fine finish coating

- High material flow rate

- High transfer efficiency

- Light weight objects