SMART Pumps

Think Smart, as for your performance as for the environment

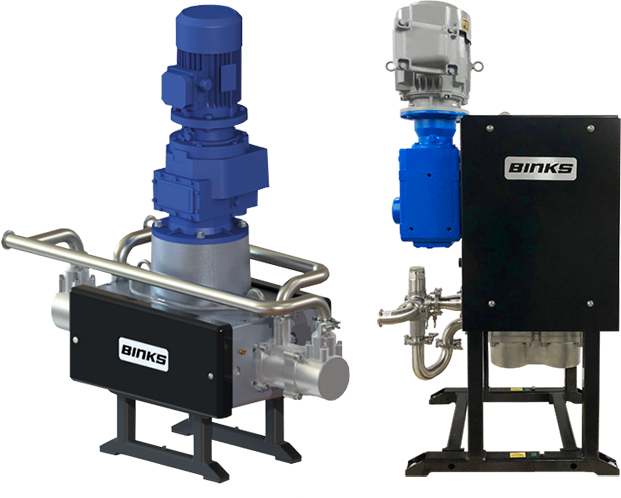

The unit combines conventional electrical hardware to achieve optimum operating performance at a lower cost. Running costs are much lower than compressed air driven model.

Used with an optional smart card, high savings in running cost can be realized, by delivering the paint to the user point at the correct pressure and volume only when needed.

The SMART pump range uses a standard electric motor to drive the fluid section for pumping paints, solvent and other suitable materials, reducing paint shear due to the positive dissplacement piston design and thanks to a cam and cam followers combined with a sliding carriage unit without required surge chamber.

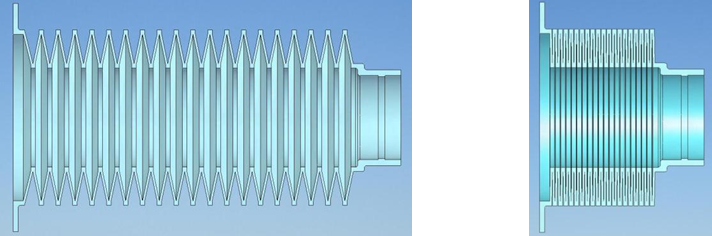

Very recoverable against bending stress

Features

- Fluid Seal:

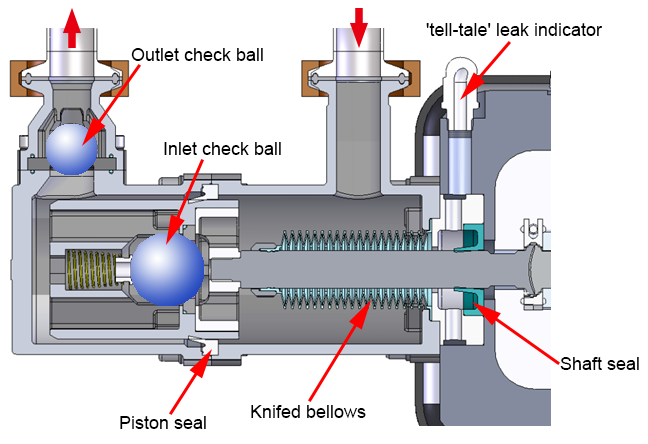

Piston seal lubricated by paint on both sides, increasing seal life / No external paint leaks when seal requires replacement - Sanitary inlet and outlet connections guarantee a smooth internal pipe connection without paint entrapment pockets

- Bellows Seal:

no exposed shaft seal reducing the need for maintenance and lubrication of shaft packing (perfect for light & moisture sensitive materials) - Flow Rate Control:

adjusted operation speed by standard AC frequency inverter to achieve a speed range from 10 to 40 cycle / min - infinite manual or automatic control - Reciprocating drive:

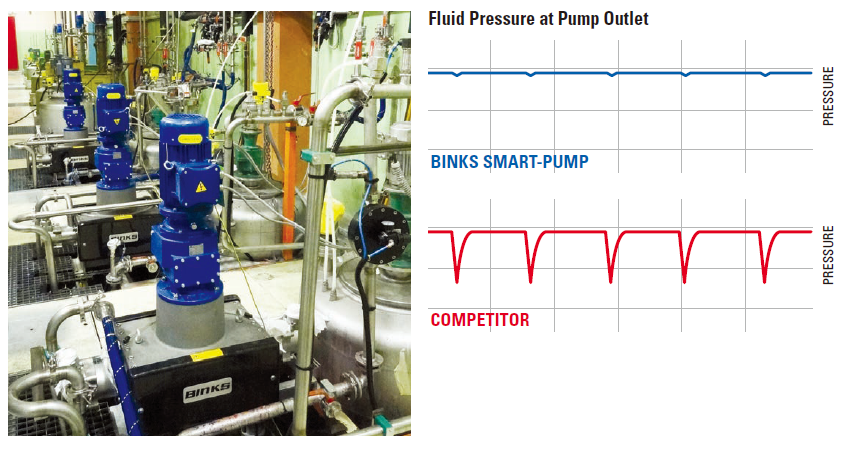

achieved by a sliding carriage mechanism & rotating constant velocity cam with special profile reducing fluid pressure fluctuations to a minimum (no surge chamber required)

- Operation mode:

Simple flow mode like a conventional air motor driven pump or by pressure control to achieve maximum «Smart» energy savings - Horizontal Short Stroke Design:

Equal thrust on both pistons / equal flow and pressure for both strokes / higher cycle rate than conventional vertical Pumps and thus more flexibility for paint flow range - Fluid sections:

Tungsten carbide ball seats & ceramic coated pistons to maximize operating life between servicing / capability for pumping abrasive & aggressive materials

Proven Technology

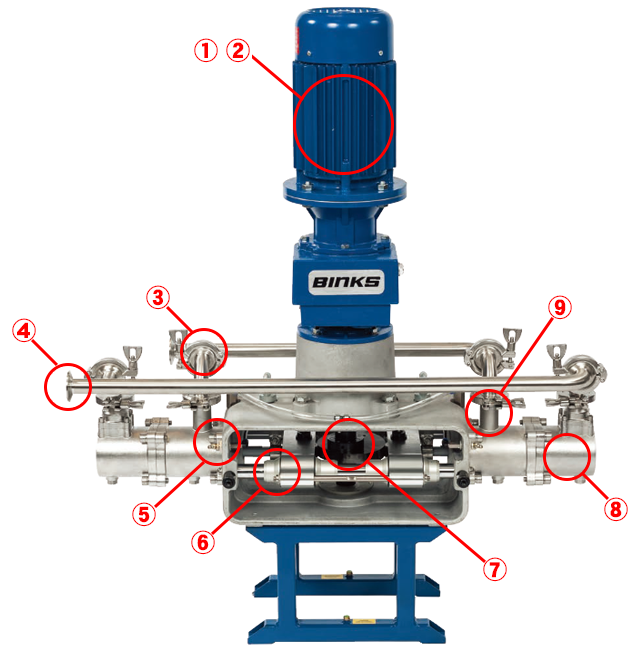

①Low power consumption electric motor, combined with Binks Smart System, delivers significant energy savings over conventional pneumatic pumps.

②AC frequency inverter removes further energy loss caused by conversion to DC.

③New manifold elbow connections for easier configuration and installation.

④Universally available sanitary fittings guarantee a smooth interior connection with no paint trap pockets.

⑤New Auto-Lubrication System provides correct automatic lubrication for up to a year. Meets new ATEX requirements.

⑥Horizontal Short Stroke Design gives equal thrust from both pistons, allowing a wider cycle rate (10-40 cycles/min) and greater flexibility of flow rate.

⑦Patented reciprocating drive incorporating sliding carriage mechanism with asymmetric constant velocity cam, gives a smooth transition and virtually eliminates material pressure fluctuations.

⑧Horizontal fluid sections compatible with shear sensitive solvent and water based materials.

⑨Internal ‘Fail-safe’ bellows seal with ‘tell-tale’ leak indicator.

Specifications

| E2-15 | E2-30 | E2-40 | E2-60 | |

|---|---|---|---|---|

| Nominal stoke | 50mm / 1.97" | 60mm / 2.36" | ||

| Max fluid pressure | 1.8 MPa | 1.8 MPa | 1.6 MPa | 1.8 MPa |

| Fluid output from 20Hz to 80 Hz | 3.75 L~ 15 L | 7.5 L~ 30 L | 10 L~ 40 L | 15 L~ 60 L |

| Flow Volume / Cycle | 0.375 L | 0.75 L | 1 L | 1.5 L |

| Fluid connections | Inlet and outlet 1" Sanitary | Inlet and outlet 1 ½" Sanitary | Inlet and outlet 1 ½" Sanitary | Inlet and outlet 1 ½" Sanitary |

| Pump weight | 78 kg | 250 kg | 250 kg | 295 kg |

| Electric motor | EU/USA: 400V, 3PH, 1kW JPN: 400V, 4PH, 0.75kW |

EU/USA: 400V, 3PH, 2kW JPN: 400V, 4PH, 1.5kW |

EU/USA: 400V, 3PH, 2kW JPN: 400V, 4PH, 1.5kW |

EU/USA: 400V, 3PH, 3kW JPN: 400V, 4PH, 2.2kW |

Accessories

| E2-15 | E2-30 | E2-40 | E2-60 |

|---|---|---|---|

| PRV22-U-10 - Pressure relief valve- 1" Sanitary | PRV22-U-15 – 1 1/2" Sanitary Pressure Relief Valve | ← | 5PRV22-U-15 – 1 1/2" Sanitary Pressure Relief Valve |

| 192547 Pressure Transducer (0 ~ 4.0 MPa) | ← | ← | ← |

| 502144 Pressure switch range (2 ~ 4.0 MPa) | ← | ← | ← |

| 192720 Sensor Manifold | ← | ← | ← |

| 502501 BPR Control Box | ← | ← | ← |

| 192206 1" Sanitary Gasket | 192208 1-1/2Sanitary Gasket | ← | ← |

| 192209 1" Sanitary Clamp | 192209 1-1/2" Sanitary Clamp | ← | ← |

EV2-30

Small footprint vertical pump

| EV2-30 | |

|---|---|

| Nominal stoke | 50mm / 1.97" |

| Maximum fluid pressure | 2.0 MPa |

| Fluid output from 20Hz to 80 Hz | 7.5L~ 30L |

| Flow Volume / Cycle | 0.75L |

| Fluid connections | Inlet and outlet 1 ½" Sanitary |

| Pump weight | 256 kg |

| Electric motor | EU: 400V, 3PH, 1.5kW |

![]() BINKS SMART Pumps - Troubleshooting

BINKS SMART Pumps - Troubleshooting