Maple Pupms

For an efficient and environmentally friendly Paint Circuit

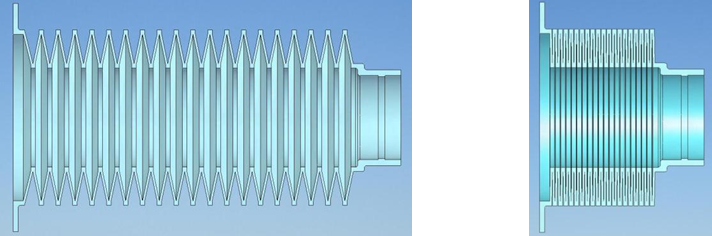

The Maple Pump is a bellows pump for pumping solvent / waterborne paints, solvents or other materials. The unit combines an energy efficient air motor with fluid technology developed from Smart Electric pumps to ensure balanced fluid pressure output and a minimum of fluid pressure fluctuations.

The Maple Pump has achieved air motor’s stable movement due to the innovative air switching valve (patented) which is designed with the magnet used spool and sleeve to make high-speed switch possible, and avoid stalling.

The air motor also utilizes the patented Binks Low Ice quick exhaust technology to prevent air valve freezing conditions when high cycle speeds are employed.

Features

- High Quality materials and surface treatments:

ensure extended operational life, including Stainless steel fluid sections, ideal for waterborne, solvent based and other paints - Fluid Seal:

Piston seal lubricated by paint on both sides, increasing seal life / No external paint leaks when seal requires replacement - Stroke Counter Port:

Option to monitor Pump life cycle data - Horizontal Short Stroke Design:

Equal thrust on both pistons / equal flow and pressure for both strokes / higher cycle rate than conventional vertical Pumps and thus more flexibility for paint flow range - Fluid Sections:

Tungsten carbide ball seats & ceramic coated pistons, ensure maximum operating life / capability for pumping aggressive and abrasive materials. - Low Ice Air Motor:

No Lubricator required / Control Valve uses quick exhaust technology (Patented design) / no risk of valve icing and stalling - Bellows seal:

No exposed shaft seal packing eliminating maintenance and lubrication of the shaft packing / Vital to the user when pumping Light (UV) and Moisture sensitive (Catalyst) materials - Control Valve:

Robust Metal spool and sleeve valves for long service life, incorporating magnetic detent to eliminate stall condition (Patented design) - Fluid Connections:

Inlet & outlet connections / smooth internal pipe connection without paint entrapment pockets

Very recoverable against bending stress

Specifications

| MAPLE 15/3 | MAPLE 30/3 | MAPLE 60/3 | MAPLE 7/7 | MAPLE 7/15 | MAPLE 8/25 | |

|---|---|---|---|---|---|---|

| Continuous cycle rate Intermittent cycle rate | 20 cycles/min & 40 cycles/min | |||||

| Flow Volume / Cycle | 0.375 L | 0.75 L | 1.5 L | 0.175 L | 0.2 L | |

| Equivalent Flow at 60 cycles/min | 22.5 L | 45 L | 90 L | 10.5 L | 12 L | |

| Air volume per cycle | 9.3 L /Cycle-0.62 MPa | 18.5 L /Cycle-0.62 MPa | 39.7 L /Cycle-0.62 MPa | 18.5 ℓ /Cycle-0.62 MPa | 39.7 L /Cycle-0.62 MPa | |

| Ratio | 3 : 1 | 3 : 1 | 3 : 1 | 7 : 1 | 15 : 1 | 25 : 1 |

| Air inlet pressure | 0.1~0.62 MPa | --- | --- | --- | --- | |

| Max fluid pressure | 1.8 MPa | 1.8 MPa | 1.8 MPa | 5 MPa | 9 MPa | 15 MPa |

| Air inlet size | 3/8" BSP / NPS | 3/8" BSP / NPS | 1/2" BSP / NPS | 3/8" BSP / NPS | 1/2" BSP / NPS | |

| Inlet/outlet fitting | 1" Sanitary | 1-1/2" Sanitary | 1-1/2" Sanitary | 1"Sanitary / 1/2"NPTF | 1"Sanitary / 1/2" NPTF | |

| Air fitting | 3/8" NPS / BSP | 3/8" NPS / BSP | 1/2" NPS / BSP | 3/8" NPS / BSP | 1/2" NPS / BSP | |

| Weight | 21 kg | 35 kg | 65.5 kg | 28 kg | 30 kg | 40 kg |

Accessories

| MAPLE 15/3 | MAPLE 30/3 | MAPLE 60/3 | MAPLE 7/7 | MAPLE 8/25 |

|---|---|---|---|---|

| 192821: Heavy Duty Mufflers | ← | ← | ← | ← |

| 192779: Exhaust Adapter 1" NB hose |

← | ← | ← | ← |

| 192803: Exhaust Plug | ← | ← | ← | ← |

| 192532: 1"Sanitary /1-1/2" BSPT(F) |

192820: 1"Exhaust Tube Adapter (1-1/4"NB) |

← | ← | ← |

| 192009: 1" Sanitary Clamp |

192009: 1-1/2" Sanitary Clamp |

← | 192009: 1" Sanitary Clamp |

← |

| 192206: 1" Sanitary Gasket |

← | 192008: 1-1/2" Sanitary Gasket |

← | 192206: 1" Sanitary Gasket |

Maple15/6 New

Ratio 6:1 / Max Fluid Pressure 4.2Mpa / Weight 45.5kg