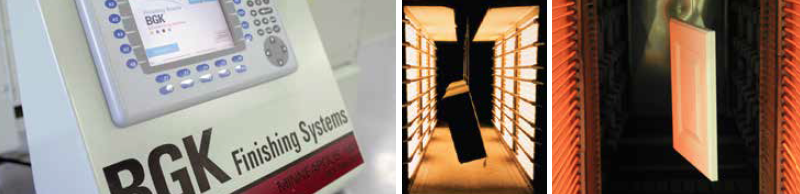

BGK Gas Convection Ovens

We Set The Standards For Reliability Regardless of Curing Method

Hot Air convection oven provides the cost effective solution for startups requiring batch parts processing capabilities, and Gas Ovens offer the best alternative in areas where electricity costs are high.

Hot Air Convection Oven

- Used in applications where NO zone curing, optical pyrometers or varied curing might be required.

- Custom configured to meet exact specifications.

- Typically used in standard applications where a part requires a uniform cure.

- Used where regulated cure areas or varied temperature ranges are not issues.

Gas Ovens

BGK ovens serve three basic purposes:

Drying

…applied to products that have a lot of moisture, usually introduced by some previously applied chemical or coating process. In drying, the oven moves a constant stream of heated air over the products to take the moisture out.

Baking

…technique is applied to heat objects over a period of time without drying them out and curing the coating to the part.

Curing

…a slower process during which an object or compound is heated to give it different properties and alter its molecular structure. IR curing can provide zoned control to meet any finishing requirement or part configuration for optimum performance.

BGK Sets The Standards For Oven Performance and Reliability Regardless of Curing Method

Flash Off Ovens

Typically used between coating allowing the coating to bake or dry and release the initial solvents.

- Flash off time helps prevent bubbling or blistering caused by insufficient evaporation time.

- Helps reduce rework by providing proper evaporation before entering a curing oven or a second coating process.

Gas Ovens

The best alternative in areas where electricity costs are high.

- Typically used in standard applications where a part requires a uniform cure.

- Used where regulated cure areas or varied temperature ranges are not issues.

Hot Air Convection Oven

The cost effective solution for startups requiring batch parts processing capabilities.

- Used in applications where NO zone curing, optical pyrometers or varied curing might be required.

- Custom configured to meet exact specifications.

Infrared Smart Oven

Designed for test coatings and processes on customer sites.

- Provides valuable data to assist process development

- Simulates an accurate and repeatable testing environment

Flat Glass Oven And Drying Systems

Meets a wide variety of requirements for the glass market.

- Focused on the application of high intensity infrared technology.

- Compact design utilizing T3 short-wave infrared emitters

- Provides unmatched drying capabilities and energy efficiency

Glass Preheat Ovens

Available in a full range of efficient wave length control for rapid, uniform heat up and accurate input temperature control.

- In glass applications, bond strength is dramatically improved at the gasket and glass interface.

- Close loop temperature control delivers glass to the injection mold process at the desired temperature.

Infrared Booster Ovens

These versatile ovens are modular in design, have been engineered for use with all coating types and can be configured to meet all parts sizes and shapes.

- Particularly effective where increased line speeds and multiple control zones are required to achieve productivity objectives.

- Features energy efficient, instant on/off emitter control performance.